Carbon fiber materials can perfect deduce "energy conservation and environmental protection" and "lightweight" two concepts, rail vehicles in the car hood seat frames, bogie and car body structure and wall panel, roof, partition, seat frames, the driver table and interior components can make use of carbon fiber composite material, lightweight in the implementation of car body weight significantly at the same time, reduce fuel use and emissions, and improve the speed of the car. The high strength of the material itself, high tensile load force and minimal deformation also guarantee the safety of the vehicle. But the inside of the car is enclosed space, high-speed operation, the interior environment of the car has the higher demand for the structure material and interior material of the vehicle body. In order to further meet the needs of rail transit equipment for vehicle safety, wuxi via new material technology co., LTD. Specializes in high-speed railway vehicles such as the particularity of operation, the development of carbon fiber composite material, resistance to high temperature fire while maintaining the original mechanical strength, corrosion resistance, radiation resistance, damp and hot advantages at the same time, improve the wearability of composites, toughness and wave permeability, in case of high temperature or the accidents such as fire, can the performance of the low smoke, low toxicity and low thermal release, greatly improving the rail traffic safety and stability of the vehicle. By promoting the application of carbon fiber in the orbit vehicle, the Chinese high-speed rail will be promoted to the world.

Energy efficiency, new energy cars and carbon fiber

The development of electric vehicles, fuel cell cars made in China, 2025 will continue to support, the strategic route strategy to take the more complete industrial system and innovation system, and promote energy saving and new energy vehicles with independent brands international advanced level.

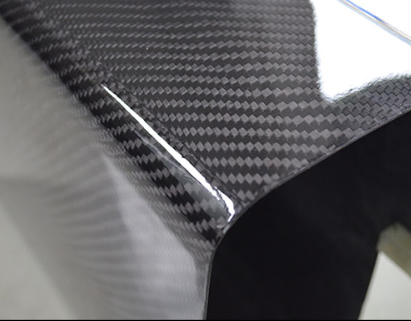

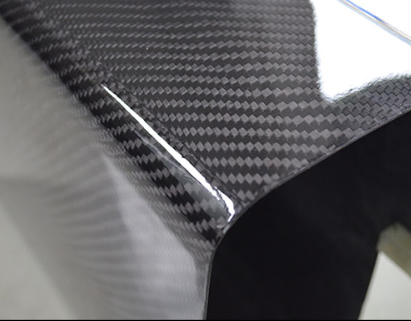

Tradition of new energy vehicles in the car, on the basis of application of carbon fiber positive, there must be more applications, because it is in order to solve energy consumption, reduce weight, reduce charging frequency, prolong the service life of the battery has a stronger demand, especially in reducing pollution and energy consumption, this is the new energy car value and meaning from the traditional cars. In this case, the government's strict fuel-economy standards and carbon-dioxide emissions laws encourage new energy vehicles to choose carbon-fibre composite materials. The weight of the electric car than a conventional car more than 200-300 kg, in order to ensure the electric car trip range has good and affordable costs, the body weight of the electric car must lose weight more than 50%. In all lightweight materials, carbon-fibre composite materials are the only alternative to steel parts, reducing weight to 50-60% and providing the equivalent strength of advanced materials.

In addition to the exterior cover, the frame, car, interior, equipment, friction, battery box and so on are all applicable to the composite materials. Via the new material technology co., LTD in wuxi for new energy vehicles, the structure of carbon fiber carbon fiber can suction box, anticollision beam and battery box body are relatively typical applications, such as a volume of about 35 l, wall thickness of 2 mm carbon fiber battery box body, weighs 2.7 kg, compared with the traditional steel structure material of battery box can lose weight by 80%, about strength and load force to do better than the traditional sheet metal parts. A box body weight only 463 grams of carbon fiber composite materials at low speed can suction box, the whole component weight compared to the original metal materials reduced by 60% - 60%, in the face of the impact energy absorption rate is very high, even higher than other materials such as steel, aluminum, more than 4 times, high strength characteristics of carbon fiber composite materials to make the resistance and the ability to pass the impact load is very strong, therefore very suitable for use in a car crash site easily.

Electrical equipment and carbon fiber

Notification of the spirit of 2025, according to China manufacturing, new energy and renewable energy, smart grid power transmission and transformation equipment, and advanced energy storage device and the user equipment development will be actively promoted.

In terms of renewable energy equipment, wide application of carbon fiber is used as a wind power blades, in the form of its high strength, light weight, wind power is an ideal material. China's first 68-meter-long 6-megawatt blades, developed independently by the zhongfu composite group co., LTD. In lianyungang, jiangsu province, has been shipped to Europe.

In advanced energy storage devices, flywheel energy storage is a new kind of green energy storage technology, its converts electrical energy to the high speed of the flywheel, when necessary, need converted to electricity by a generator, when you don't need to do high-speed flywheel, in the process of operation and maintenance does not produce any waste chemical materials. You can discharge and discharge countless times, using very long life. The light and high-strength carbon fiber material is significant to the energy storage flywheel, and the development and utilization of carbon fiber storage and flywheel are more and more widely available at home and abroad.

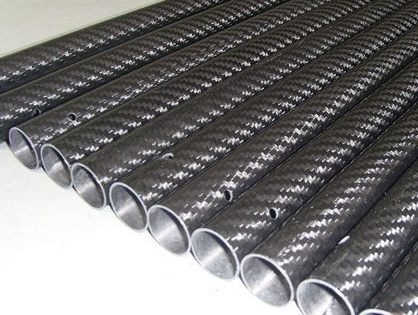

In terms of the smart grid power transmission and transformation and client devices, state grid is applied to the whole country a substation inspection robot intelligent work effect is remarkable. Is independent of charging methods used by the robot, filled with a runnable 5-6 hours, every charge of devices for at least two rounds of comprehensive inspection, patrol at least 2 hours per round, as a result, the robot of the electrical energy storage should be used to detect as far as possible. In order to ensure the robot tolerated for a longer time of the high strength work, the inspection robot via the wuxi new material technology co., LTD. Production of extensible carbon fiber casing mechanical arm, the robotic arm by merely to narrow tubes seven different types of arm, wall thickness ranging from 0.5 mm to 2 mm, total weight only 3 kg, greatly reduce the energy consumption when the robot inspection, so as to prolong the working time, improve the working efficiency. In addition, carbon fiber has good corrosion resistance and fatigue resistance, in a larger temperature difference also can maintain a minimum creep, so the inspection robot can apply to high altitude, extreme heat, cold, wind, dust and rain sub-station under the bad environment.

Farm equipment and carbon fibre

Chinese-made 2025 strategic requirements focus on developing large grain and strategic economic crop breeding, cultivation, kind of, tube, collecting, transporting and storage etc. Mainly used in the production process of advanced agricultural machinery equipment, speed up the development of high-end agricultural equipment and key parts and components, improve agricultural machinery and equipment information collection, intelligent decision-making and accurate operation ability.

As an agricultural country, how to concentrate effectively detect crop growth condition and spraying is one of the high-end agricultural equipment is actively solve the problem, has managing pesticide usage and operation of high precision, prevention and control of the agricultural plant protection function with good effect through the way of long-distance remote control operation, help staff to avoid direct contact with the pesticide spraying, spraying to improve the security, and more accurate way to a great extent, reduce the cost of resources. Drones for agricultural monitoring will be able to master crop growth in a timely and accurate manner and provide reliable information for agricultural practices.

Carbon-fiber composite materials, such as carbon fiber paddle, carbon fiber and carbon fibre wall tube, are the main material of the unattended mechanism. Accounted for a quarter of the carbon steel material, good flexibility, high specific strength, tensile strength is 10 times more than ordinary steel, excellent creep resistance and shock resistance, good durability and corrosion resistance at the same time, the corrosion of acid, alkali, salt and atmospheric environment has certain weight-bearing, can effectively extend the service life of unmanned aerial vehicle (uav).

High performance medical devices and carbon fiber

As the focus of national economy and people's livelihood, the medical device industry has become one of the key points of China's 2025 strategy. Its stressed that must improve the innovative ability of medical equipment and the level of industrialization, focus on developing imaging equipment, medical robots and other high performance medical equipment and medical products.

With an increasing number of cancer patients worldwide, radioactive rapidly rising demand for medical devices and radioactive diagnosis and treatment of equipment with the development of technology has gradually towards the direction of the small dose of radiation and digital imaging analysis, on the use of radioactive medical equipment and auxiliary equipment, relevant accessories for X ray through the performance is good, in meet the under the premise of as much as possible to reduce the radiation harm to patients and medical staff, at the same time, these parts strength and durability to meet the requirements of equipment used in high frequency, in terms of quality, health, reliability and accuracy are required to conform to the standard parameters of high standard medical equipment. Carbon fiber composite materials have the excellent properties of meet the above requirements, therefore, carbon fiber radioactive head, bed panel, radiotherapy positioning frame, mammary gland machine support plate, DR carbon fiber medical devices and diagnostic equipment such as flat panel detector has been more and more used in clinical.