News Center

Contact Us

Company:TIANJIN YUFENG CARBON CO., LTD

Telephone:022-66202074

Address:11/B.C.D Tianjin International Development Building No. 2, Dongting Road TEDA Tianjin China

Telephone:022-66202074

Address:11/B.C.D Tianjin International Development Building No. 2, Dongting Road TEDA Tianjin China

News Center

The current position:首页 >> News Center >> Industry Dynamic

The development and market analysis of Chinas carbon fibre industry in 2016

Release time:2017-06-07 10:28 Reading:

An analysis of the international carbon fiber industry

(1) the development of the international carbon fibre industry

The middle of the 20th century, developed countries invest a lot of manpower and material resources to study carbon fiber, carbon fiber composite material was originally because of its irreplaceable in the structure of lightweight material performance, first is favored in the military field of aeronautics and astronautics; Test technology in 1959, the Japanese Osaka industry into Mr. Zhao men's first invented the polyacrylonitrile (PAN) based carbon fiber, in 1964, the royal institute of aviation (RAE) watt and others through the production of high performance process of polyacrylonitrile (PAN) based carbon fibers, the fiber tension draft thermal stabilization process, in order to meet the transformation of the structure, make the polyacrylonitrile (PAN) based carbon fibers into the mainstream products, and open civil carbon fiber commercial application in the 1970 s; In the 1980s and 1990s, carbon fiber developed rapidly under the guidance of civil aviation. Entering the 21st century, carbon fiber production technology is mature, enlargement of the application of carbon fiber, carbon fiber market demand has increased dramatically, carbon fiber industry has become increasingly mature.

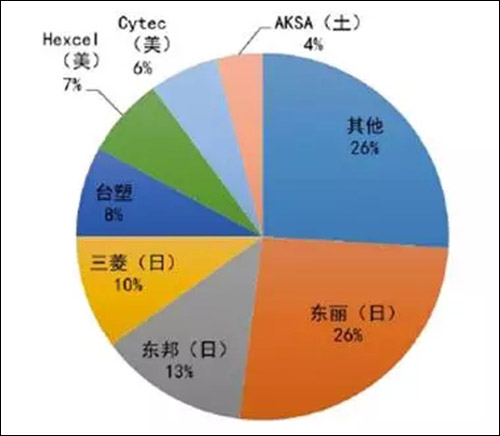

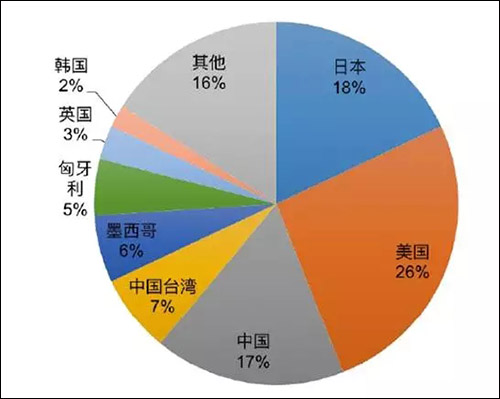

The international carbon fibre market is still dominated by Japanese and American companies, according to the market share of the global carbon fibre market. Japan is world's largest producer of carbon fiber, the carbon fiber technology mainly in the hands of the Japanese company, the production of carbon fiber is a world leader in both quality and quantity, Japan toray high-performance carbon fiber research and production in the world of "leader".

The data shows that Japanese companies account for 49% of global production in the fibre market. In the large tow carbon fiber market, Japanese companies have market share accounted for 52% of global production capacity, the market share of U.S. companies have accounted for 24% of global capacity, the japan-american total of the two countries has 76% of the world's large tow carbon fiber production capacity, is in obvious dominance.

A map of the market share of fibre-fibre markets worldwide

Global carbon fiber market share map

(2) international carbon fibre market and trend analysis

A. global carbon fibre market demand and trend analysis

Carbon fiber rarely direct application, mostly through deep processing into intermediate or composite materials, carbon fiber composite material as a structure or function has been widely used in aerospace, industrial and sports leisure products three areas. Carbon fiber with light weight, high strength, high modulus, high and low moderate corrosion resistance characteristics of the earliest application in aerospace and defense, such as large aircraft, military aircraft, unmanned aircraft and missile, rocket, satellite and radar cover, etc., and aerospace fields using carbon fiber performance level is the highest relatively. In the field of industry, carbon fiber is widely used in automotive, cable, wind power, pressure vessel, Marine industry, electronics, industrial equipment and civil construction, etc.; In the field of sports leisure products, golf clubs and fishing rods for the earliest applications, in recent years, cycling, tennis rackets, badminton racket sports products also more and more use of carbon fiber material, generally use grade T300 carbon fiber can meet the demand, but in order to improve product performance, some parts have also started to use T700 carbon fiber level even higher performance.

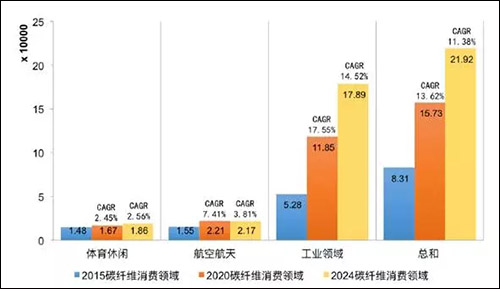

With the continuous development of carbon fiber, carbon fiber in the field of industrial and aerospace application scope expands unceasingly, in the field of proportion is on the rise, also predicts 2020, demand of carbon fiber, the amount will reach 157300 tons, the average annual compound growth rate of 13.62%; Overall demand in the world is expected to reach 21.92 million tons by 2024, although the growth rate has slowed, but the compound growth rate is still 11.38 percent. The fastest growing industry, with a combined growth rate of 14.52 per cent over the next decade, has seen a combined growth of 17.55 per cent over the past five years. The proportion of carbon fibre consumption in the industrial sector will rise from 63.55 per cent in 2015 to 81.63 per cent. Demand in the field of aerospace into rapid growth in the next five years, while the sports leisure areas in the world within the scope of application is relatively mature, demand has been increasing steadily each year.

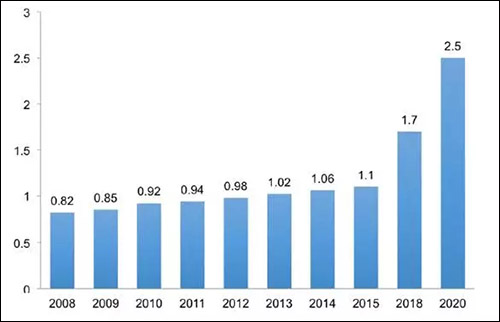

Global carbon fibre market demand forecast (metric ton)

A. the aerospace sector is growing in demand

Carbon fibre composites are the ideal material for large monolithic structures. It can reduce the weight by 20% to 40% compared to conventional materials. Composite materials also overcome the vulnerability of metal materials to fatigue and corrosion, increasing the durability of the aircraft. The good formability of composite materials can greatly reduce the cost of structure design and manufacturing cost. Aerospace field demand for carbon fiber is mainly from two aspects, one is increasing the proportion of carbon fiber composite materials, the second is the new orders, is expected in 2020, the aerospace demand for carbon fiber will reach 22100 tons.

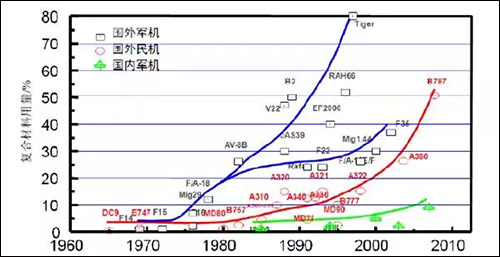

Due to the carbon fiber composite materials in the structure of lightweight irreplaceable material performance, is widely used in the application field of military aviation and rapid development, since the 1970 s, foreign military aircraft from the initial components manufacturing composite materials used in the tail level to today for wing, flap, before the body, in the fuselage, fairing, etc. Since 1969, the United States F14A fighter dosage of carbon fiber composite material is only 1%, to the United States F - 22 and F35 to represent the fourth generation of fighters on the carbon fiber composite materials dosage is 24% and 36%, in the United States - 2 B stealth strategic bomber, carbon fiber composite material proportion is more than 50%, increasing dosage. With composite material components can not only realize the lightweight and design degrees of freedom, but also the overall forming, reduce the number of parts, reduce the production cost and improve production efficiency.

The application of composite materials for military aircraft in China is also increasing. With carbon fiber composite materials in the defence aerospace application proportion increase, equipment list with increase in the number and the need of equipment upgrading of update, the late national defense demand for carbon fiber will increase year by year.

Composite materials are used in the application of aviation products

Starting in the 1980 s, carbon fiber composite materials start application in the plane of the bearing components, in the early days of the A310, B757 and B767, carbon fiber composite materials accounted for only 5% - 5%, along with the advance of technology, carbon fiber composite materials gradually as time bearing components and the main bearing components used in aircraft, its quality proportion also began to gradually improve, to the A380, the composite material proportion reached 23%, the specific application in aircraft main load-carrying structure components such as main wing, tail, next to the body, the central wing box, pressure, etc., time load-carrying structure components such as auxiliary wing and rudder and aircraft interior materials, created the advanced composite materials in large aircraft on large-scale application of precedent. The latest B787 and A350, the dosage of the composite material reached more than 50%, there are more parts using carbon fiber, such as the nose, tail, the wing skin and so on, to enhance the usage. In terms of orders, the A350 2015 orders as of October 2015, Boeing B787 is more than one thousand, C919 aircraft though composite materials used by less than 20% in China, but the order quantity has more than 400. The huge demand for aircraft is enough to support long-term carbon-fibre demand.

Composite materials in the commercial aircraft application scale trend chart

In addition, in recent years the UAV (UAV) including the fighter jets (UCAV) is developing rapidly, due to low cost, light structure, high mobility, high overload, high stealth, the technical characteristics of long distance, determines its urgent need to lose weight, the use of composite materials proportion basic is the highest of all aircraft, the Global Hawk (Global Hawk high-altitude long-endurance UAV common composite material was 65%, and the dosage of advanced unmanned aerial vehicle (UAV) composites is improved, 45 c, X X - - 47 b, "neurons" and "thor" are using 90% of the composite materials. In recent years, unmanned aerial vehicle (uav) in addition to the widely used for military purposes, patrolled the disaster and environmental monitoring, geodetic aerial photography and weather observation USES more and more widely in the field of civil, as the plane form batch production, will continue to increase in the amount of composite materials on the unmanned aerial vehicle (uav).

In the field of aerospace, carbon fiber composite material not only accord with the requirement of structure materials of space technology to reduce the quality, also accord with the structural material with high specific modulus and specific strength, which has the function of performance and can design, by a large number of applications. In addition, the weight of the shuttle every 1 kg less, can relieve the carrier rocket 500 kg, therefore, widely used in the aerospace industry advanced carbon fiber composite materials. The United States and Europe have less than 10 percent of the total weight of their satellites, because of the widespread use of high-performance composite materials. At present, the satellite's microwave communication system, energy system and various supporting structures have basically been made of composite materials. In terms of the carrier rocket and strategic missile, carbon fiber composite material with its superior performance got better application and development, has been successfully used in "pegasus", "delta" carrier rocket and the trident Ⅱ (D5), such as "dwarf" missile model; The us strategic missile MX intercontinental missile, the Russian strategic missile "poplar" M missile, is used in the advanced composite launcher.

High power and long blade demand accelerate the carbon fiber of wind turbine

Wind power is one of the representatives of clean energy, which is favored by countries around the world. Since its commercialization in the 1980s, it has experienced the rapid growth of globalization. By the end of 2015, the global total installed capacity of 432.42 GW, the cumulative annual growth rate of 17%, according to the forecast of GWEC, global wind power cumulative installed capacity will be increased from 369.6 GW in 2014 to 666.1 GW in 2019, the compound growth rate as high as 12.5%. Wind power in the future development direction, in addition to emerging areas, such as Latin America, Africa and other places to exploit market, low speed blower fan and sea will gradually become the hot spot.

For economic reasons, the current mainstream of blades for glass fiber reinforced plastic (GFRP) material, but with low speed and the continuous development of sea fan, fan blade length increasing, part of the structure using carbon fiber and carbon fiber/glass fiber hybrid materials in the comprehensive cost will be an advantage. According to estimates, more than 40 meters key structures such as beam in wind-power blades cap, girder using carbon fiber composite materials on the one hand can make the blade weight decreased by 38%, 14% lower cost; On the other hand, it can improve the fatigue performance of the blade, improve the output power, and make it easier to produce large diameter and adaptive wind blades with carbon fiber.

C. Innovation in the car industry brings demand in the carbon fiber industry

As stricter emission standard and the low carbon life is accepted by the people, has become an important research topic in the automotive industry for energy conservation and emissions reduction, in the case of energy innovation co., LTD., one of lightweight is the key to solve the problem. Carbon fiber has the outstanding advantages of high modulus and ratio, high potential and good safety, which is the best choice for car. According to the European aluminium association, fuel efficiency can be increased by 6% to 8% if car quality is reduced by 10%. In absolute terms, the weight of the car is reduced by 100kg per 100 kg, and 0.6 liter per 100 Km of fuel, and the co2 emissions can be reduced by about 10g/Km. Since 1953, the world's first car full composite material body - GM Corvette manufacturing success, along with the advance of composite technology, now carbon fiber composite materials in the automobile body, tail, automotive chassis, engine cover, car interiors, and other places. BMW i3 is a large quantity of carbon fiber composite materials, weight loss of about 250-350 kg, and has set a successful example for quantifying automobile.

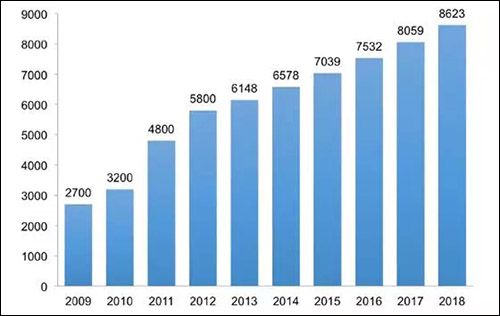

With the continuous development of automobile industry, especially in the new energy vehicles is popular today, the market of automobile lightweight, energy saving and environmental protection needs to put forward the higher request, under the automotive lightweight demand, since 2009 the global auto industry is on the rise, the demand of carbon fiber of carbon fiber composite materials application proportion rising in the field of auto industry. The forward-looking industry institute conservative estimates, the future demand of carbon fiber in the field of auto industry will keep the size of the 7% growth, according to the growth forecasts, by 2018 global demand of carbon fiber in the field of auto industry will be around 8600 tons.

Carbon fibre demand forecast (tons) in the automotive industry

Famous consulting Research organizations Lux Research released in February 2015, the latest report, with the rapid development of material technology, by 2020, carbon fiber composite materials market valuation is expected to reach $6 billion, to 2025, carbon fiber composite materials is expected to become the mainstream of the global auto market configuration.

B. global carbon fibre supply

The global carbon fiber industrialization product still represented by PAN based carbon fiber, its mechanical performance is the highest, the most widely application field, more than 90% of the total global carbon fiber production.

The world's PAN base carbon-fibre production capacity was about 128,000 tons in 2014, of which about 92, 000 tonnes of small strands of carbon fibre were made, accounting for 72% of the total. Large bundles of carbon fiber are about 36, 000 tons, or 28 percent. In 2014, the total production of carbon fibre in the world was about 90,000 tons. According to the forecast that by 2020, the global small tow carbon fiber production capacity will reach 115000 tons, the big tow production capacity of 54000 tons, total 169000 tons, the compound growth rate of 7%.

Status and forecast of global carbon fibre production

Current global leader of the carbon fiber is Japan and they set up factories in Europe and the United States, the second is to rely on the healthy development of the European and American aerospace market HEXCEL and CYTEC companies in the United States, and Germany SGL companies rely on strong industrial innovation system, with the increase of test in the field of carbon fiber in China, China's carbon fiber production share of the world also continue to improve.

The global production quota for carbon fibre countries

Domestic carbon fiber industry analysis

(1) the development of the domestic carbon fiber industry

Beginning in the 1960 s in China r&d polyacrylonitrile based carbon fiber, the earliest engaged in carbon fiber research and development institutions mainly for shanxi MeiHuaSuo of Chinese academy of sciences, changchun institute of applied chemistry, chemical research institute (Beijing). Over the past 50 years, China's carbon fibre industry has grown from nothing to large, but the development rate is still slow compared with developed countries. Over the past 15 years, under the country's strong support, has achieved a major breakthrough in the domestic carbon fiber industry, carbon fiber and its application in the field of technology and industrialization degree appeared to accelerate the development momentum, into an unprecedented new stage of development, initially formed in home is given priority to with jiangsu, shandong and jilin carbon fiber industry. According to statistics, in 2010-2014 period, China's carbon fibre production capacity from 6445 tons to 15000 tons, has increased by 2 times, the average annual growth of 23.5%, at present, the production of carbon fibers are all small tow, 90% more than 12 k, 1 k, 3 k, 6 k production.

(2) domestic carbon fibre market analysis

According to statistics, in 2015 the domestic carbon fiber market demand is about 11000 tons, with the development of the national economy and defence industry to further improve the strategic position, in the next few years demand of carbon fiber in our country will enter a period of rapid growth, is expected to be domestic demand of carbon fiber in 2020 will reach 25000 tons, the annual growth rate of about 15.5%.

Domestic carbon fibre market demand (MMT)

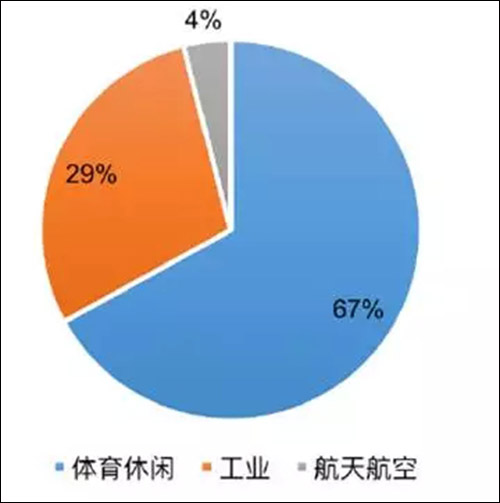

At present, the proportion of domestic carbon fiber in aerospace, sports leisure and industrial applications is 4%, 67% and 29%. Among them, sports leisure accounted for the vast majority, in the new energy equipment, transportation, civil aviation, engineering construction application, although already started, but application level is low, the design level of carbon fiber composites is insufficient, lack of form a complete set of material, the relevant application standard system is not sound, lead to narrow application field. In addition, resin, sizing agent and other supporting material varieties, performance, less composites with auxiliary materials have not yet fully realization of supply, some varieties are dependent on imports, etc., not only restricts the application of carbon fiber composite materials in the high-end products, but also seriously affect the application of domestic carbon fiber market.

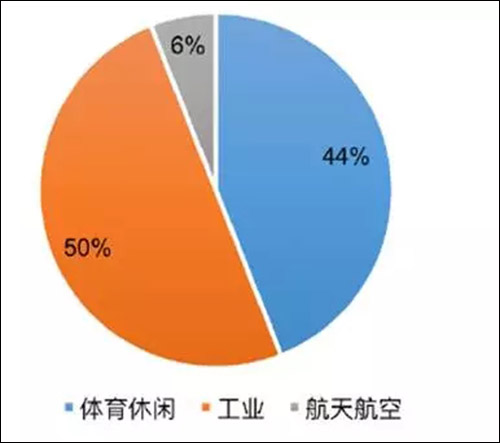

The future along with the further development of basic industries, the application of carbon fiber in industry scale will improve, is expected in 2020, the domestic carbon fiber in the aerospace, sports leisure and industrial application of the dosage of the three areas of 6%, 44% and 50%, demand structure to move abroad.

Domestic carbon fibre market demand share chart in 2014

2020 domestic carbon fibre market demand share chart

According to statistics, at present domestic carbon fiber market, its self-sufficiency rate of domestic carbon fiber is only about 20%, the foreign dependency rate of 80%, carbon fiber abroad enterprises through technical and price advantage on the domestic carbon fiber, carbon fiber market in China is subject to long-term Europe and the United States and Japan and other countries. The price of high performance carbon fibre as a sensitive defense strategy is not only subject to market law, but also to national defense policies in both countries. With the continuous development of domestic high performance carbon fiber technology and industrialization, in order to ensure the security and avoid long-term enslaved monopolize the domestic market and foreign enterprises, national relevant policies, to promote domestic high-performance carbon fiber is widely used in the field of aerospace and other defense. The future of China's new equipment requirements of growing defence and the national policy of civil-military integration deepening, domestic high-performance carbon fiber will continue to maintain good growth momentum.

(3) problems with the development of the domestic carbon fibre industry

A: most carbon fiber enterprises have A large gap in technical equipment, manufacturing process and international advanced enterprises, and low production capacity

In November, 1949, 17 in developed countries, led by the United States, founded the "coordinating committee", its main purpose is to restrict members strategic materials and high technology exports to the socialist countries, included in the list of military weapons and equipment, advanced technology products and three major categories of thousands of kinds of products such as rare material. On April 1, 1994, "coordinating committee", has been dissolved but the embargo items list is it for later inherited the tile at agreement, which contains two control list: a list is a dual-use goods and technology, covering the advanced materials, materials processing, electronics, computer, telecom and information security, sensor and laser, navigation and aviation electronic instruments, shipbuilding and maritime equipment, 9 categories such as propulsion system; The other is a list of military items covering 22 categories, including weapons, ammunition, equipment and combat platforms, and China is still in the list of banned countries. So far, aerospace equipment needed for the high-end carbon fiber as a strategic material, unable to import for a long time, in the production of carbon fiber core technology and advanced facilities can't introduce, severely restricted the defense industry and the development of carbon fiber industry in our country.

At present, foreign equipment used carbon fiber leading enterprises are basically designed according to their own characteristics, on the basis of proprietary equipment improvement to upgrade, formed with independent intellectual property rights and proprietary carbon fiber production equipment; And the domestic imported foreign production equipment is an unembargoed generic carbon fibre production equipment, and the price is higher. Although the domestic carbon fiber production enterprises in the design production capacity more than thousand tons of a 3-4, but because of the lack of core technology team, most of the carbon fiber production enterprises of imported production equipment technical parameters and performance index of the lack of digestion and absorption capacity, production line automation degree and the suitability of its carbon fiber production technology lags far behind foreign counterparts, lead to the stability of the production process and the consistency of the process control is bad, affect the carbon fiber product quality and stability, and the production cost is very high, cause equipment idle, operating losses, cannot compete with the international advanced enterprises. In 2014, the actual production of carbon fiber in China was only 3, 200 tons, and the cumulative production of carbon fiber in 2007-2014 was only 12,300 tons, well below the design capacity.

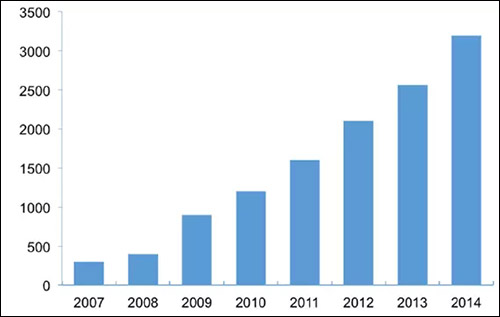

Domestic carbon fibre actual production chart (ton)

Most carbon-fibre products are in the lower end of the market and are not highly concentrated in the industry

Can be seen from the development of global carbon fiber industry, the aerospace and defense industry is a carbon fiber is the most important application areas, consumption of about 30% of the world total consumption, but accounted for 50% of the world's carbon fiber production; Compared with the development of abroad, carbon fiber market mainly around the sports leisure industry development in our country, accounting for more than 65%, however, the niche market belongs to the low end of the field, very big price competition pressure. At present our country engaged in carbon fiber composite materials research and production unit nearly hundred, but can produce high performance carbon fiber of the aerospace standard enterprise a handful, a large number of enterprises focus in the field of sports leisure, the vast majority of the carbon fiber manufacturers are still in red. With the evolution of the market economy, the carbon fiber industry will face reshuffle, with independent intellectual property rights, and continuous innovation ability of enterprises will be in the future competition.

C. domestic carbon fibre manufacturers lack the core technologies and talents to meet the requirements of high performance carbon fiber in aerospace and high-end civilian areas

The production technology of high performance carbon fiber is complicated, the process is long, the link is more, the subject is more, and the equipment manufacturing ability is closely related. With giant carbon fibers (cf) abroad, compared to decades of continuous accumulation of our country most of the carbon fiber production enterprises lack of mastering the core technology research and development and production personnel, and industrialization of research and development team is not stable, the early stage of the technology and data accumulation deficiency, lack of technology research and development of the laboratory, pilot technology industrialization of amplification, engineering construction of the whole technology experience, thus in preparation, such as quality, cost, equipment and technology with foreign and larger gap. The lack of long-term, stable research and technology teams has become an important constraint on the core competitiveness and sustainable development of the carbon fibre industry.

D. the industrial chain of carbon fiber in our country needs to be further improved

At present, foreign countries have formed the system of carbon fiber composite materials, which is designed, manufactured, analyzed and verified, and applied traction systemically. Like Japan toray heck Selma and the United States have presoak cloth, fabric, short cut fiber, sandwich materials and other intermediate shape, at the same time, directly to provide clients with tailor-made solutions and products, composite materials is convenient for the use of customers, and solve the problem of the carbon fiber products and resin matching.

Because most of the domestic carbon fiber composite materials technology is not mature, lack of corresponding research and development and process support, failed to form a systematic and series of carbon fiber industry chain development model.

(4) the trend of the development of the domestic carbon fibre industry

Carbon fiber industry development space is huge, not only reflected in the defense industry of carbon fiber and the urgent need of strategic emerging industries, but also in the rapid expansion of the national economy every field of application.

The rapid development of the aerospace industry and the deepening of the integration of military and civilian areas provide A development opportunity for the new materials industry represented by carbon fiber

In the long run, China's defense construction lags behind economic development and does not match the rising power status of our country, which is not conducive to stabilizing the complex environment. Commensurate with China's international status at present, the construction of national defense strength, to reform of national defense and the army into the overall situation of national comprehensively deepen reform has risen to national level strategic moves. In recent years, the military and civilian integration has become the overall strategy of economic development and national defense construction, is the power within the period of dream, the motherland's important strategic deployment.

As a new generation of the material basis for the national defense equipment, accelerate the development of new materials technology is an important premise to maintain the leading position of military, carbon fiber composite materials in recent years broader application field and development is very rapid, its use has become a measure of an important symbol of advanced military equipment. In the future, the area of defense construction of carbon-fibre materials will be expanded in the future with the new equipment of national defense and the renewal of existing equipment.

In the aerospace sector, our fighter jets are based on three or four generations of aircraft, and five generations of aircraft have not yet been commissioned, and older aircraft have a higher proportion. According to the international flight data, about 60% of the military aircraft in China is facing a retirement, for fourth and fifth generation fighter for signs of a new generation of combat power, it will promote the demand of military aircraft to a great extent, the development of the military aircraft manufacturing industry provides a rare opportunity, will boost the demand for high-end carbon fiber composite materials.

In the field of conventional weapons and equipment, upgrading of China's weapons is an urgent need to use of lightweight, high strength, corrosion resistance of carbon fiber composite material, has got the attention of related customer, the future market space is huge.

Compared with developed countries, there is a huge demand for domestic carbon fiber, and the development structure will be further optimized

The current domestic civil sports leisure class accounted for the vast majority of the applications of carbon fiber, and in the new energy equipment, rail transportation, civil aviation, engineering construction application, although already started, but application level is low.

High-speed economic growth, as the national air transport demand, the central and local government increasing investment in civil airport construction, civil airport construction new development climax, greatly promoted the domestic civil aviation industry, the rapid development of passenger demand surge in the number. According to Boeing, China needs 1764 commercial aircraft by 2020, the largest market outside the us. At the same time, the commercialization of large domestic passenger aircraft, which is represented by the C919, provides greater opportunities for the development of carbon fiber in civil aviation.

The future along with the further development of basic industries, the application of carbon fiber in industry scale will improve, important potential market such as wind power equipment, automobile manufacturing, rail transportation and other fields of the future development prospect.

C. under the country's strong support, represented by Jane in science and technology of carbon fibre company, is speeding up the pace of research and development and industrialization, the products and the competitiveness of enterprises constantly improve

From the 70 s that our government began to vigorously support the development of the domestic carbon fiber, "7511" of the meeting organized by general zhang aiping, laid the foundation of national support the development of domestic carbon fiber, through "15", "11th five-year plan", "twelfth five-year" three five-year plans, strong support for the domestic carbon fiber industrialization and application technology research, engineering drawing, make the development of domestic carbon fiber has made great progress. Currently, there are four to five carbon-fibre companies that have been used in the aerospace industry to demonstrate that the T300 technology has been largely passed through. And Jane in the science and technology but also through many years' accumulation of technology, break through the level higher than that of T700 carbon fiber industrialization of engineering technology, production of ZT7 series high-performance carbon fiber has been batch used in the field of aerospace, to break the blockade in aerospace field high-end carbon fibers. In Jane is leading the domestic carbon fiber enterprises of science and technology to achieve higher performance of carbon fiber industrialization pace, using innovative technologies and equipment to reduce the production cost, improve enterprise core competitiveness.

Prev:

Next: