News Center

Contact Us

Company:TIANJIN YUFENG CARBON CO., LTD

Telephone:022-66202074

Address:11/B.C.D Tianjin International Development Building No. 2, Dongting Road TEDA Tianjin China

Telephone:022-66202074

Address:11/B.C.D Tianjin International Development Building No. 2, Dongting Road TEDA Tianjin China

News Center

The current position:首页 >> News Center >> Industry Dynamic

Carbon fiber - new hot spots in the new material industry

Release time:2017-06-07 10:42 Reading:

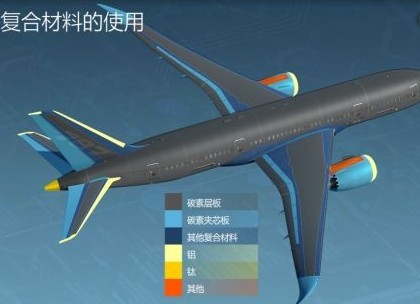

Aerospace materials has been the most advanced level, represents the application materials according to the chemical composition of different can is divided into the metal and its alloy materials, non-metallic materials, inorganic non-metallic materials and organic composite materials, which account for most of the composite proportion of carbon fiber composite materials become one of the most potential for development of advanced composite materials.

The particularity of working environment for aerospace products, its performance requirements of materials is very high, mainly reflected in the "light weight, high strength" and "high temperature resistant corrosion resistant" two aspects. The "light quality" means that the material is higher and less dense, the lighter the better. "Weatherproof" is the ability of the material to be able to withstand higher working temperature and have excellent corrosion resistance, especially against stress corrosion and fatigue resistance.

Carbon fiber composite materials are widely used in aerospace, such as rockets, missiles and high-speed aircraft, with their unique and excellent physicochemical properties. For example, a structural material of the plane: the main wing, the tail, the body; Secondary construction materials: aileron, rudder, elevator, interior material, floor board, girder, brake, etc. The exhaust cone of the rocket, the bonnet of the engine, etc. Artificial satellite structures, solar panels and antennas, carrier rockets and missile shells. At present, in the small business jets and helicopters, carbon fiber composite materials have accounted for about 55% of the total materials, accounting for 25% of military aircraft, large aircraft accounted for 20%.

Today, in addition to the aerospace field, there are many industries are also vigorously develop and make use of the special value of carbon fiber composites, such as new energy vehicles and high-speed rail transit industry. For these industries, lightweight is an important criterion for product competitiveness. The new energy car battery life is one of its core technology, through the interior, equipment, warehouse, battery box, the anticollision beam and endergonic box using carbon fiber composite material to achieve weight loss effectively, reduce kinetic energy consumption, extend battery life became the common choice of the vast majority of new energy vehicles. For a section of the car body weight is up to more than 10 tons of railway vehicles, car body in starting and accelerating stage is one of the biggest energy consumption, reduce weight nature can greatly reduce energy consumption, ease of axle and wheel wear at the same time, so the use of carbon fiber composite materials production track of the vehicle inner decoration, structure has become a hot topic of the industry technology development.

Industrial areas for the use of carbon fiber composite materials also presents the situation of "flowers", in addition to the wind-power blades carbon fiber, carbon fiber sucker rod started earlier applications, such as in recent years, with the rapid development of intelligent industry, the application of carbon fiber mechanical arm got unprecedented attention. Mechanical arm, for use of carbon fiber composite materials could be on the basis of the guarantee strength, greatly reduce the weight of reducing energy consumption, and the linear expansion coefficient of carbon fiber composite materials is extremely low, even under the larger temperature difference, make the mechanical arm can still maintain good accuracy. State grid is promote the use of a nationwide distribution substation inspection robot, using the wuxi via new material technology co., LTD., the production of carbon fiber composite multilayer extensible mechanical arm, the robotic arm in to lengthen working hours and wear resistance, cold resistance, etc is a plus.

\

\Because of the good x-rays through sex, carbon-fibre composites are also an important part of a new generation of radial-medical products, favored by the medical device industry. Carbon fiber radial head and position holder frame, carbon fiber, carbon fiber breast surgery and interventional catheter bedplate machine support plate and DR flat-panel detector and so on are carbon fiber composite materials in the radioactive medical devices become more widely used.

As the important content in the planning of "much starker choices-and graver consequences-in" strategic emerging industries, the development of new materials industry is the country attaches great importance to and vigorously support, carbon fiber composite materials as a "dark horse" horse in advanced composite materials, with the attitude of "lighter and stronger", to cling to a historical opportunity for development, for China's 2025 target saving more energy, contribute more to the development of achievements.

Prev:

Next: